Introduction The term reverse polarity protection is familiar to many engineers. In most front-end power systems, especially in the field of electronic vehicles, reverse connection protection has become a key component of connecting the ECU/system to the battery.

Its main function is to prevent dynamic reverse polarity during surge events or when the inductive load is disconnected from the battery, as reverse-connected power can damage connected subsystems, circuits, and components.

Generally, Schottky diodes are the traditional choice to prevent reverse polarity conditions, but they incur power losses due to forward conduction. Detailed thermal calculations are required, leading to increased system costs and space requirements. In an era of rapid technological advancement and product iteration, we now have more convenient and efficient methods for reverse polarity protection.

Key Points of this Article In this issue, we will discuss the reverse polarity protection of Schottky diodes and MOSFETs, focusing on the reverse polarity protection of MOSFETs. We will then compare the working analysis of NMOS and PMOS in this regard.

Before that, let's briefly discuss "traditional diode protection."

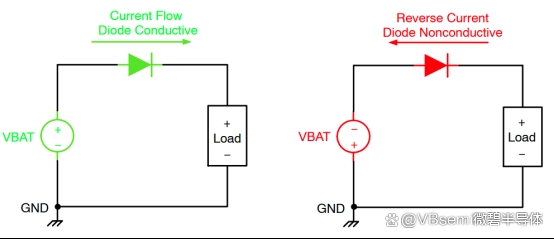

Common methods to prevent reverse polarity at the input of the system power path: add a series diode at the input.

Function: Under normal circumstances, the load current flows forward through the diode. But if the battery is connected with the wrong polarity, the diode will be reverse biased and block reverse current, thereby protecting the load from negative voltage.

This simple and traditional reverse polarity protection has some drawbacks:

Power dissipation: At higher load currents, the forward voltage drop causes significant forward conduction losses.

Thermal management (as mentioned earlier): Managing power dissipation requires heat sinks, increasing overall costs and space.

Higher forward voltage drop.

Reverse leakage current: The reverse leakage current of the diode increases sharply with junction temperature, leading to higher power consumption.

Diode Reverse Polarity Protection Compared with Schottky diodes, the voltage drop of MOSFETs is generally much lower.

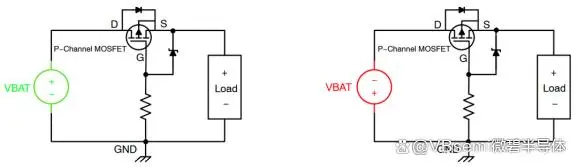

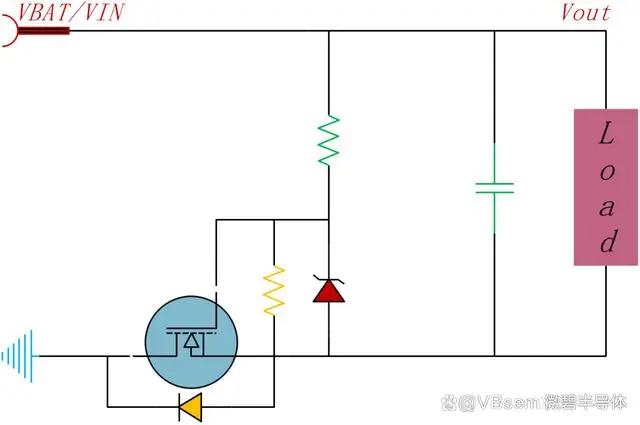

First, let's talk about reverse polarity protection using P-channel MOSFETs.

In the previous issue, we discussed the body diode of the MOSFET. Like all MOSFETs, a P-channel MOSFET has an intrinsic body diode between the source and drain.

When the battery is connected, the body diode conducts, and then the MOSFET channel conducts.

There is a prerequisite we mentioned before: to make the P MOS conduct, the gate voltage needs to be at least VT (threshold voltage) lower than the source voltage. When the battery is reversed, the body diode is reverse biased, and the gate and source voltages are the same, so the P MOS is turned off.

This is where an additional Zener diode is used to clamp the gate of the P MOS, providing protection against excessive voltage.

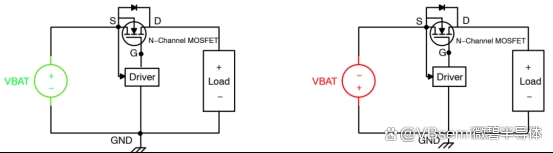

Using N-channel MOSFETs for Reverse Polarity Protection

When the battery is correctly connected, i.e., the source is connected to VBAT, to make the MOSFET conduct, the gate-source voltage (Vgs) must be higher than the threshold voltage (Vth). Since the source is connected to VBAT, the gate voltage needs to be at least Vth (threshold voltage) higher than VBAT.

Therefore, we can use a dedicated driver to drive the gate voltage of the N MOS higher than the source voltage, making the NMOS conduct. When the battery is reversed, the body diode is reverse biased, and then the driver is disabled (the source and gate are shorted), and the N MOS is turned off.

Comparison Analysis of the Three

From the above analysis, we can make a simple comparison between Schottky diodes and MOSFETs.

Schottky Diode

Advantages: Low cost, simple operation.

Disadvantages: High power loss, high voltage drop.

MOSFET

Advantages: 1. Product flexibility (different RDS(ON) MOSFETs)

Low power consumption, low voltage drop.

Disadvantages: 1. Cost of MOSFETs with low RDS(ON) is higher, and the total cost may be slightly higher (requiring additional controllers).

Some complexity.

Comparison of NMOS and PMOS Usage

We know that the operation of P MOS generally depends on the hole mobility, while the operation of N MOS depends on the electron mobility.

For the same drain current, the electron mobility is much higher than the hole mobility, almost 2.5 times. Therefore, to achieve the same on-state resistance, the chip size of P MOS needs to be larger than that of N MOS, leading to higher costs. Therefore, in reverse polarity protection, NMOS is more suitable for such applications.

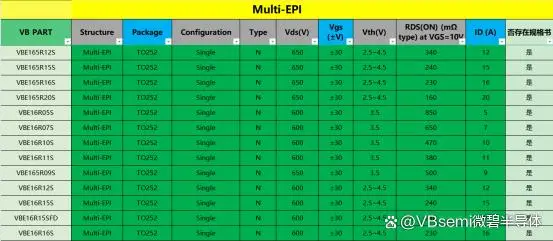

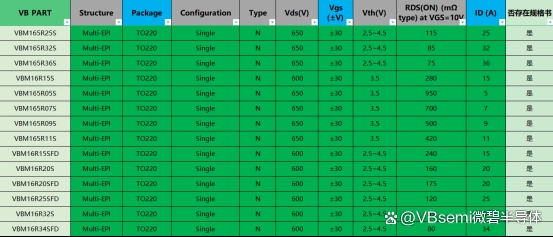

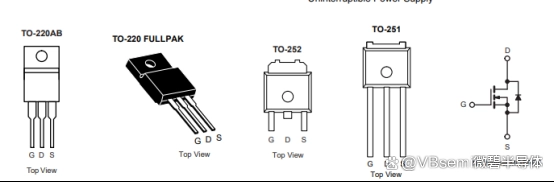

As mentioned above, choosing MOSFET products with low on-state resistance is also one of its advantages. VBsemi's MOSFET products have low on-state resistance, smaller size, and better heat dissipation capabilities, providing powerful reverse polarity and reverse current blocking.

One can choose the MOSFET that matches their application needs and various circuit designs and application scenarios.

* 如果您需要申请我司样品,请填写表格提交,我们会24小时内回复您