About Silicon Carbide

The Chinese silicon carbide industry is a highly potential industry with diverse products, deep industrial chain, and wide application areas, presenting good market development prospects.

As we all know, silicon carbide has excellent electrical properties such as high voltage resistance, high temperature resistance, high frequency, and radiation resistance. It breaks through the physical limitations of silicon-based semiconductor materials and becomes the core material of the third-generation semiconductor. The superior performance of silicon carbide material leads the new revolution of power devices.

The role of power devices is to process, convert, and control electrical energy. Power devices made with silicon carbide as the substrate have many advantages over silicon-based power devices, such as high voltage resistance, high temperature resistance, low energy loss, and high power density, which can realize the miniaturization and lightweight of power modules. Compared with silicon-based MOSFETs of the same specifications, the size of silicon carbide-based MOSFETs can be greatly reduced to 1/10 of the original, and the on-state resistance can be reduced to at least 1/100 of the original. The total energy loss of silicon carbide-based MOSFETs of the same specifications is much lower than that of silicon-based IGBTs, reducing by 70%.

Silicon Carbide Applications (In the Field of New Energy)

New Energy Vehicles

Silicon carbide power devices are mainly used in the electric drive and control systems of new energy vehicles. Compared with traditional silicon-based power semiconductor devices, silicon carbide power devices have many obvious advantages in terms of voltage resistance, switching losses, and high-temperature resistance, which help to achieve lightweight and high-efficiency electric drive systems for new energy vehicles. They are widely used in key electric drive and control components of new energy vehicles, such as main drive inverters, OBCs, DC/DC converters, and non-vehicle-mounted charging piles.

Major mainstream new energy vehicle manufacturers are actively deploying silicon carbide models.

Silicon carbide devices are used in on-board charging systems and power conversion systems, which can effectively reduce switching losses, improve the limit working temperature, and enhance system efficiency. Currently, more than 20 automobile manufacturers worldwide use silicon carbide power devices in on-board charging systems; silicon carbide devices are used in new energy vehicle charging piles, which can reduce the volume of the charging pile and increase the charging speed. The application of SiC in new energy vehicles will greatly reduce the weight of the vehicle while ensuring its strength and safety performance, effectively improving the driving range of electric vehicles by more than 10% and reducing the volume of the electronic control system by 80%.

The market space for silicon carbide in fast DC charging piles is expected to increase significantly in the future. Due to cost considerations, the current proportion of silicon carbide devices used in DC fast charging piles is relatively low. However, by configuring silicon carbide power devices, DC fast charging piles can greatly simplify internal circuits, improve charging efficiency, reduce the volume and cost of heat sinks, and reduce the overall size and weight of the system. With the application of 800V fast charging technology, the silicon carbide market for DC charging piles is expected to grow rapidly.

Silicon Carbide Photovoltaic Power Generation

In photovoltaic power generation applications, traditional inverters based on silicon-based devices account for about 10% of the system cost but are one of the main sources of energy loss in the system. The use of silicon carbide MOSFETs or power modules combining silicon carbide MOSFETs with silicon carbide SBDs in photovoltaic inverters can increase the conversion efficiency from 96% to above 99%, reduce energy loss by more than 50%, and increase the device's cycle life by 50 times, thereby shrinking the system size, increasing power density, extending device life, and reducing production costs. High efficiency, high power density, high reliability, and low cost are the future development trends of photovoltaic inverters. In string and centralized photovoltaic inverters, silicon carbide products are expected to gradually replace silicon-based devices.

Benefiting from the world-leading level of technology and industrial scale in emerging industries such as 5G communication and new energy, the huge application market space for silicon carbide devices in China is driving the rapid development of the upstream semiconductor industry, and domestic silicon carbide manufacturers have their own advantages. In the context of global shortage of semiconductor materials, international leading enterprises have proposed plans to expand the production capacity of silicon carbide and maintain high R&D investment. At the same time, domestic SiC manufacturers are accelerating their layout in the field of silicon carbide, seizing development opportunities, and catching up with international leading enterprises.

VBsemi is an enterprise specializing in the design, manufacturing, and sales of semiconductor devices. Its newly developed silicon carbide MOSFET (SiC MOSFET) adopts silicon and wide-bandgap technology, with advantages such as higher power efficiency, smaller size, lighter weight, and lower overall cost. This product is suitable for high-voltage scenarios above 600V, including photovoltaics, new energy vehicles, charging piles, wind power, and rail transportation in the field of power electronics.

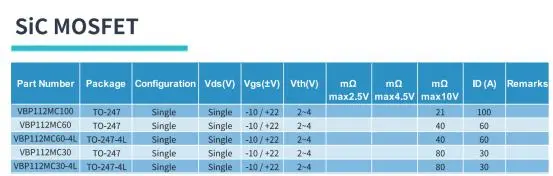

Below are VBsemi's SiC products:

VBsemi SiC Products Product Packaging

VBsemi's products include SOT23, DFN, SOT-89, SOP-8, TO-92, TO-251, TO-252, TO-220, TO-220F, TO-263, TO-247, SOT-223, TO3P, TO262, SOT669, TSSOP8, SC70, DIP8, SC75, SOT725, and other series of packaging products, which can meet various needs of users.

Application Fields

VBsemi's products are widely used in the automotive field: electronic control, battery management, on-board inverters, on-board electronic products, charging piles, etc.; communication field: various power supplies, switches, etc.; industrial field: inverters, frequency converters, power tools, etc.; home appliance field: fans, washing machines, sweepers, refrigerators, air conditioners, etc.; consumer electronics field: lighting, medical equipment, wireless charging, mobile power supplies, etc., and the product quality has always remained at the top level in the industry.

* 如果您需要申请我司样品,请填写表格提交,我们会24小时内回复您