Silicon carbide (SiC) material has attracted wide attention and research due to its superior physical properties. When Tesla announced the Model 3, the market began to focus on the initial niche areas of silicon carbide's appearance. So what role does silicon carbide play in the field of electric vehicles? Why is it receiving so much attention?

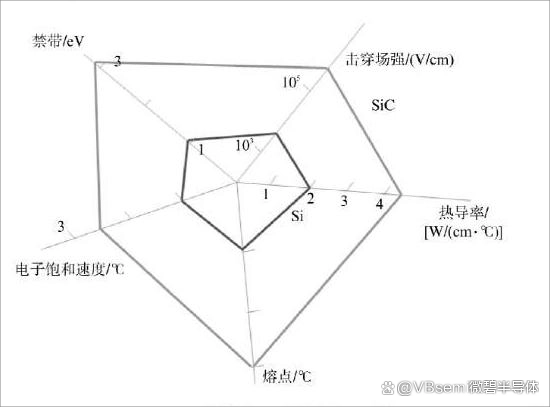

First, let's understand the characteristics of silicon carbide. Compared with the widely used Si material, SiC material has a higher thermal conductivity, which determines its high current density characteristics. However, its higher bandgap width also determines the high breakdown field strength and high operating temperature of SiC devices. Its advantages can be summarized as follows:

High-Temperature Operation

SiC has a highly stable crystal structure, with a bandgap width of 2.2eV to 3.3eV, almost twice that of Si material. Therefore, SiC can withstand higher temperatures, and generally, the maximum operating temperature of SiC devices can reach 600 ºC.

High Breakdown Voltage

Compared with Si material, the breakdown field strength of SiC is more than ten times that of Si, so the breakdown voltage of SiC devices is much higher than that of Si devices.

Low Losses

Generally, the conduction losses of semiconductor devices are inversely proportional to their breakdown field strength. Therefore, at similar power levels, the conduction losses of SiC devices are much smaller than those of Si devices. Moreover, the conduction losses of SiC devices have little dependence on temperature. The conduction losses of SiC devices change very little with temperature, which is significantly different from traditional Si devices.

Fast Switching Speed

The thermal conductivity of SiC is almost 2.5 times that of Si material, and the saturation electron drift mobility is twice that of Si, so SiC devices can operate at higher frequencies.

Combining the above advantages, at the same power level, the number of power devices in the equipment, the volume of the heat sink, and the volume of filtering elements can all be greatly reduced, while the efficiency can be significantly improved.

So, how does silicon carbide play a crucial role in the field of electric vehicles?

The emergence of silicon carbide can to some extent balance the weight and durability of electric vehicles. In the power control unit, silicon carbide devices can make batteries lighter, longer-lasting, and stronger. Silicon carbide devices can also shorten charging times.

With the increase in the penetration rate of new energy vehicles, the application and status of silicon carbide in electric vehicles are becoming more and more important. The automotive industry is an important pillar industry of the national economy, playing an important role in the national economic and social development. With the sustained and rapid development of China's economy and the accelerated urbanization process, the demand for automobiles will continue to grow for a long time to come. With the increase in the penetration rate of new energy vehicles, the application and status of silicon carbide in electric vehicles are becoming more and more important.

Similar to the pursuit of higher-performance processors in mid-to-high-end smartphones, silicon carbide can not only improve the energy conversion efficiency of new energy vehicles but also improve the overall cost of the vehicles, although the higher price will cover this part of the cost. Therefore, to obtain more industry profits, various manufacturers' mid-to-high-end vehicles will also be equipped with silicon carbide devices.

Due to the characteristics of silicon carbide (SiC) material, Sic MOSFET, as a third-generation wide bandgap power semiconductor, has significant advantages over the second-generation power semiconductor mainly based on Si material. It greatly reduces losses in conduction resistance, switching, etc., and is suitable for higher operating frequencies. Moreover, due to its high-temperature operating characteristics, it greatly improves high-temperature stability. As shown in the figure below (Comparison between Sic and Si).

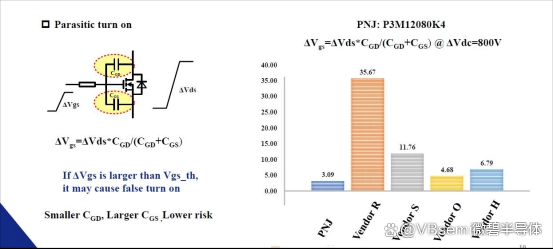

However, Sic-MOSFET also has its drawbacks. It can achieve faster switching speeds and higher efficiency in practical applications, but its fast switching speed puts higher demands on the design of the driving circuit, especially the stray inductance of the entire system, which can cause significant EMC impact at fast switching speeds.

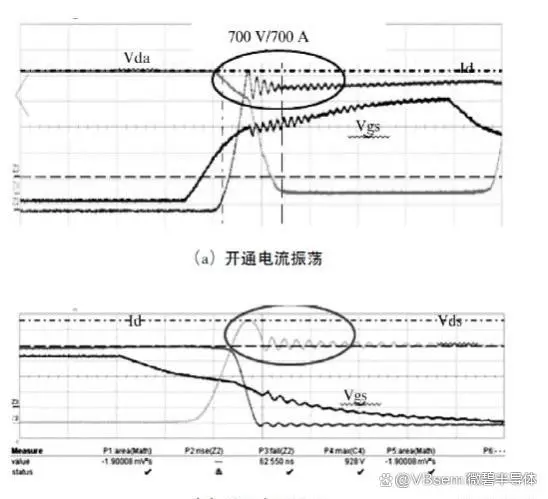

Similarly, Sic-MOSFET still faces significant challenges in terms of electrical performance. Due to its faster response capability, current and voltage oscillations are prone to occur.

The following figure shows the switch current and voltage oscillation curves of SiC MOSFET modules, where (a) is the turn-on current oscillation, (b) is the turn-off voltage oscillation, and (c) is the diode oscillation voltage, with the peak reaching 856V. From these three figures, it can be seen that the electrical oscillations of SiC MOSFET during switching are much more severe than those of IGBTs, presenting significant challenges for automotive-grade applications and EMC aspects.

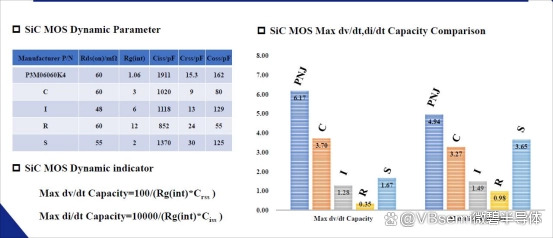

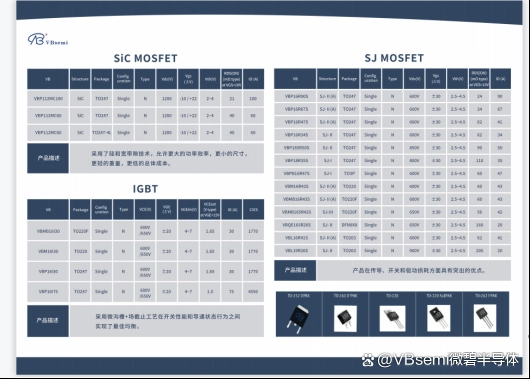

(VBsemi's Sic-MOSFET product parameters)are shown in the figure below:

* 如果您需要申请我司样品,请填写表格提交,我们会24小时内回复您