Question One:How to modify the MOSFET that burns out in a dual N-channel MOSFET buck circuit?

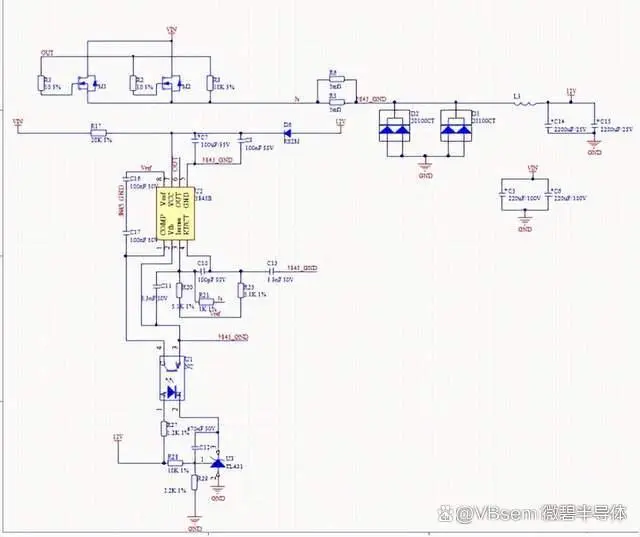

In a 48V to 13V non-isolated buck DC circuit, after setting a 25A load, when powered on for testing, one of the MOSFETs on the board burns out. Replacing the faulty MOSFET resolves the issue.

When using an oscilloscope to test the good MOSFET, the DS voltage is at most 64V, which is lower than the manual's specified maximum of 80V. The gate threshold voltage is 15V, lower than the manual's specified maximum of 25V. The MOSFET's switching time (rise and fall time) is short enough, and the product has current limiting protection, which pulls the voltage down to 9-10V at 30A.

How should I measure and analyze this?

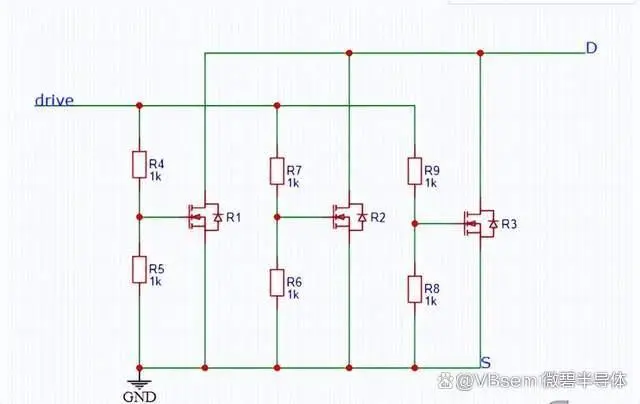

Question Two: How to configure the drive resistor for parallel MOSFETs, and how to determine the turn-on voltage?

Parallel MOSFETs can increase the current capability. What characteristics of the MOSFETs should be considered when paralleling them, such as turn-on and turn-off delay times, and turn-on voltage?

Are the connections above correct?

Previous Answers:

Previous Answer One: Only when the switching device is off will the leakage inductance affect it, because once it is off, a counter electromotive force will be generated due to this leakage inductance, which can easily breakdown devices like MOSFETs. For the leakage inductance shown in the diagram, a simple understanding is that, during conduction, the induced voltage is positive above and negative below, and the MOSFET is conducting at this time, so this positive above and negative below induced voltage will not damage the MOSFET.

Previous Answer Two: After the MOSFET is turned on, the channel mainly conducts in reverse, because the body diode itself has a relatively large voltage drop, about 0.7V, and the channel essentially shorts the body diode.

* 如果您需要申请我司样品,请填写表格提交,我们会24小时内回复您