MOSFETs are fundamental components in electronic manufacturing. However, when faced with various packages, characteristics, and brands of MOSFETs, how should one choose? Is there a simple and efficient selection method?

Choosing the right MOSFET can effectively control manufacturing costs. More importantly, it matches the product with the most appropriate component, ensuring optimal efficiency, stability, and durability in the device's future use.

So, how should one choose among the myriad of MOSFETs on the market? Below, we outline 7 steps to elucidate MOSFET selection requirements.

Step 1: Determine N and P Channel Selection

MOSFETs come in two structural forms: N-channel and P-channel. Since their structures differ, the polarity of the voltage they use also varies. Therefore, before choosing which product to use, it is essential to determine whether to adopt an N-channel or P-channel MOSFET.

Step 2: Determine Voltage

The higher the rated voltage, the higher the cost of the device. Therefore, it is necessary to determine the required rated voltage, i.e., the maximum voltage the device can withstand. In practice, a sufficient voltage margin must be left to provide adequate protection to prevent MOSFET failure.

Step 3: Determine Current

The determination of current depends on the circuit structure. The rated current of the MOSFET should be the maximum current that the load can withstand in all situations. Similar to voltage, the rated current of the MOSFET must meet the demands when the system generates peak currents.

Step 4: Determine Thermal Requirements

After determining the current, the system's heat dissipation requirements must be calculated. Designers must consider the worst-case scenario for heat dissipation, as this result can provide a larger safety margin to ensure that the system does not fail.

Step 5: Determine Switching Performance

The most crucial step in selecting a MOSFET is determining its switching performance. Many parameters affect switching performance, but the most important are gate-source, gate-drain, and drain-source capacitances. Calculating total losses during MOSFET switching is necessary to understand the device's overall power.

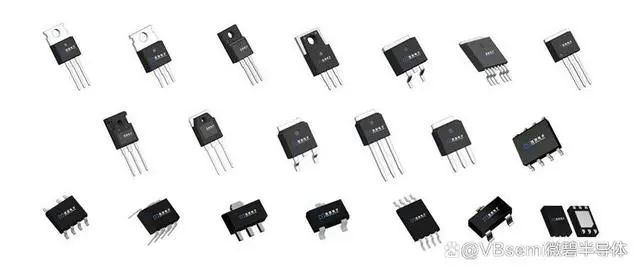

Step 6: Consider Packaging Factors

MOSFETs of different package sizes have different thermal resistances and power dissipation capabilities. When selecting parameters and packaging, the basic principle is to choose power MOSFETs with more universal parameters and packaging, while ensuring the temperature rise of the power MOSFET and system efficiency.

Step 7: Choose the Right Brand

There are many manufacturers of MOSFETs worldwide, broadly categorized into European and American, Japanese, Korean, Taiwanese, and domestic Chinese companies. Each has its advantages and disadvantages, and the choice depends on factors like brand value, technological advantages, and price considerations.

In conclusion, mastering MOSFET selection involves understanding various parameters and considerations, ranging from electrical characteristics to thermal performance and brand reputation. By following these seven steps, engineers can navigate the complexities of MOSFET selection more effectively, ensuring optimal performance and reliability in their electronic designs.

This passage discusses the manufacturers of MOS transistors (Metal-Oxide-Semiconductor Field-Effect Transistors), which can be broadly categorized into several series: European and American, Japanese, Korean, Taiwanese, and domestic Chinese.

European and American Manufacturers: Represented by companies like STMicroelectronics, ON Semiconductor, Texas Instruments (TI), Power Integrations (PI), and Infineon. These companies have long dominated the high-end market due to their brand value and technological advantages, although their products often come with higher price tags.

Japanese Manufacturers: Mainly including Toshiba, Renesas, and others. Japanese companies possess rich experience and technological expertise in the semiconductor field, holding a certain position in the market.

Korean Manufacturers: Such as KEC, AUK, and Sionsemi. While Korean MOS transistor companies may lag slightly behind their European, American, and Japanese counterparts in technology, they often offer competitive pricing, making them important suppliers in the industry.

Taiwanese Manufacturers: Including VBsemi, APEC (Fudan), and CET (Huaray). Taiwanese companies hold a certain market share in the semiconductor industry, with some having strong competitiveness in the mid-to-low-end and niche markets.

Domestic Chinese Manufacturers: Examples include VBsemi, Silan Microelectronics, Huahong Group, and Dongguang Micro. Leveraging local advantages and fast customer service response, domestic Chinese companies have strong competitiveness in the mid-to-low-end and niche markets. Some are also striving to penetrate the high-end market to meet local demands.

* 如果您需要申请我司样品,请填写表格提交,我们会24小时内回复您