A netizen asked VBsemi to discuss third-generation wide bandgap semiconductors.

Currently, the third-generation semiconductors mainly include Silicon Carbide (SiC), Gallium Nitride (GaN), and Zinc Oxide (ZnO).

Among these, Silicon Carbide has garnered considerable attention in recent years due to its applications in industries such as industrial, photovoltaic, and automotive sectors. Especially in electric vehicle applications, Silicon Carbide has brought in quite a bit of "big money." Today, let's delve deeper into this "Silicon Carbide" material.

Silicon Carbide: Formed by the combination of carbon and silicon, it's an artificially synthesized semiconductor material. The substrate of Silicon Carbide is a p-type semiconductor, positively charged, similar to the conduction principle of conventional silicon MOSFETs.

(High level: Conducting Low level: Cutoff)

However, compared to silicon MOSFETs, Silicon Carbide boasts much stronger power performance.

Why is it called a "wide bandgap semiconductor"?

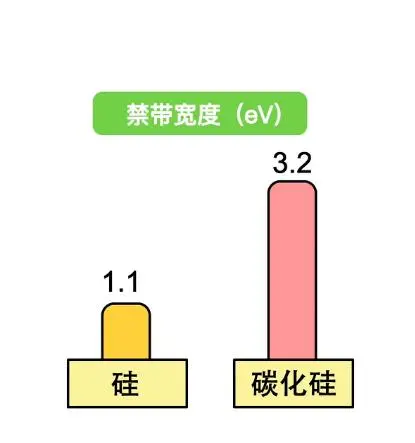

Generally, an important reference value to measure the superiority of a semiconductor's performance is its bandgap width.

The bandgap width of silicon is approximately 1.1 electron volts, whereas the bandgap width of Silicon Carbide is nearly three times larger, almost reaching 3.2 electron volts, hence the term "wide bandgap."

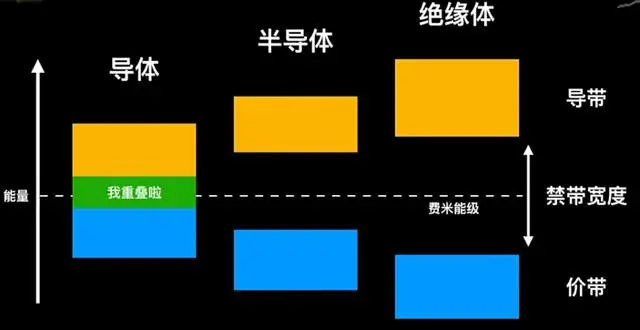

So, what is the significance of this "bandgap width"?

This is because the wider the bandgap, the more difficult it is for the material to conduct electricity.

VBsemi found this image online, which illustrates it well: the wider the bandgap, the more the properties lean towards an insulator. Silicon Carbide fits this description, making its properties more stable.

Particularly in terms of area, power consumption, power, electron mobility, high voltage, and high temperature, Silicon Carbide has significant advantages.

For example, in terms of voltage resistance, it takes 300,000 volts to break down 1 cm of silicon, whereas it takes 2.2 million volts to break down Silicon Carbide.

Furthermore, in terms of area, after the MOSFET is turned off, when the voltage is applied to the Silicon Carbide substrate, due to its voltage-resistant advantage, the device area of Silicon Carbide can be much smaller than that of silicon devices.

Thermal conductivity and high temperature resistance are also well-known features of Silicon Carbide, making it a significant factor in its application in electric vehicles. The thermal conductivity of Silicon Carbide is nearly three times that of silicon MOSFETs, indicating its strong heat dissipation capability.

In high-temperature environments, Silicon Carbide devices can operate at temperatures above 200°C, whereas silicon devices can only handle up to 150°C.

Moreover, the high switching speed and high-frequency advantages of Silicon Carbide significantly reduce switching losses, making it slightly superior to Insulated Gate Bipolar Transistors (IGBTs) in electric vehicle applications!

For example, in the same electric vehicle, using Silicon Carbide devices can increase the vehicle's endurance by five percent.

In recent years, major automotive companies have invested heavily in Silicon Carbide, and even Huawei has made frequent moves. Silicon Carbide is so good, are there no other drawbacks?

Yes, it's expensive.

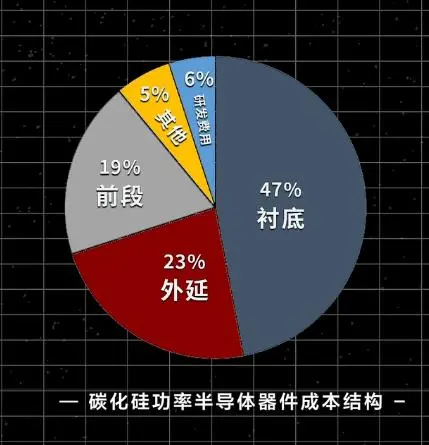

Currently, the main costs of Silicon Carbide lie in epitaxy and substrates, with substrates (Silicon Carbide) accounting for nearly 47% of the cost.

The cost of Silicon Carbide is about four times that of silicon, mainly due to production issues.

Silicon Carbide has relatively strict process requirements;

Its wafer size is small, with few manufacturers capable of production, and capacity is still increasing;

Silicon Carbide is extremely hard, with a hardness second only to diamond.

This cost factor will keep silicon devices as the long-term choice in the market.

So, can third-generation semiconductor Silicon Carbide eventually replace silicon?

In some application areas, Silicon Carbide can indeed be substituted.

However, it cannot be said to "replace" silicon because the two are not continuous; they simply differ in material, with each having its own advantages. Silicon MOS and related low- to medium-voltage power MOS devices still have significant advantages in some ultra-low-voltage and medium-voltage fields. Meanwhile, Silicon Carbide MOS is mainly used in high-temperature and high-voltage scenarios, posing no significant conflict.

Furthermore, Silicon Carbide is currently mainly used for power devices, and due to its higher gate voltage, it's not yet applicable to integrated circuitry. Of course, the rapid pace of technological advancement means this won't be a limiting factor.

Finally, let's briefly discuss Gallium Nitride (GaN).

A few days ago, a member in the group mentioned that GaN is already being used in some industrial fields.

However, in reality, compared to Silicon Carbide (SiC), GaN's application scope is quite limited. Moreover, most of its applications are in the ultra-high-frequency field, where driving technology is a major challenge and issues such as miscommunication and floating inductance occur frequently.

For various reasons, GaN cannot replace silicon in the short term.

Well, that's all for this issue. Creation is not easy, and if you find it helpful, we hope you'll give us your support by following us! Thank you very much for your support!

* 如果您需要申请我司样品,请填写表格提交,我们会24小时内回复您