Today, we're introducing VBSEMI's new product, the IGBT, also known as the Insulated Gate Bipolar Transistor.

In practical electronic applications, the most common electronic components are the Bipolar Junction Transistor (BJT) and MOSFET.

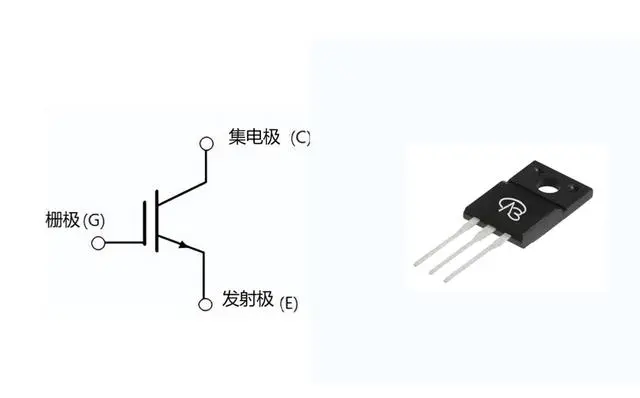

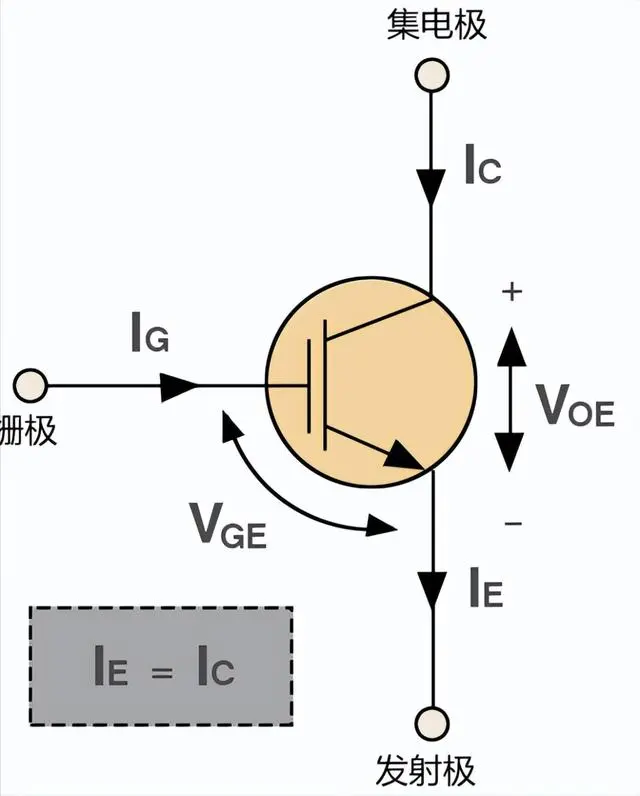

The IGBT (Insulated Gate Bipolar Transistor) can be seen as a fusion of the BJT and MOSFET because it combines the input characteristics of a BJT with the output characteristics of a MOSFET.

Compared to them, VBsemi's IGBT has a larger power gain, higher operating voltage, higher short-circuit current level, smaller chip size, lower thermal capacity, and shorter short-circuit withstand time.

Considering these advantages of IGBTs, in this article, we will discuss how VBsemi's IGBTs implement short-circuit protection in industrial motor drive applications.

First, let's look at the short-circuit withstand time of IGBTs.

Initially, people believed that the short-circuit capability of IGBTs depended on the length of time they could withstand a short circuit. However, in many cases, the short-circuit withstand time cannot accurately represent the actual short-circuit capability. In fact, the short-circuit withstand time is actually a thermal failure and occurs under conditions where the thermal distribution of the chip is relatively uniform. Its short-circuit withstand time is related to its transconductance or gain.

In general, a higher gain leads to a higher short-circuit current inside the IGBT. Therefore, IGBTs with lower gains have lower short-circuit levels. However, higher gains also lead to lower on-state conduction losses.

This is where the trade-offs come in.

With technological advancements, IGBTs have gradually increased their short-circuit current levels while reducing short-circuit withstand time. This has made their chip sizes smaller, shrinking the size of the modules.

IGBT Overcurrent Protection

For IGBTs, they are not inherently fault-safe components, so encountering a fault can lead to the explosion of the DC bus capacitor and the failure of the entire drive. Therefore, for overcurrent protection, it is necessary to implement it through current measurement or saturation detection.

For example, when performing current measurements, current shunts need to be added to the inverter and phase outputs for measuring devices to cope with DC bus faults and motor winding faults. The fast-acting commutation circuits in the controller or gate driver must promptly turn off the IGBT to prevent it from exceeding the short-circuit withstand time.

Under normal operation, the collector-emitter voltage of the IGBT is very low (typically 1V to 4V). However, if a short circuit event occurs, the collector-emitter current of the IGBT rises to a level that drives the IGBT out of saturation and into the linear operating region. This causes the collector-emitter voltage to rise rapidly.

In the above scenario, a normal voltage level indicates a short circuit. Usually, during desaturation, the gate-emitter voltage will be too low, and the IGBT will not be able to fully drive out of saturation, so careful detection is required to prevent false triggering. Typically, a current source charging capacitor or an RC filter is also added to generate a brief time constant in the detection mechanism.

Under normal operation, it is recommended that the gate driver be designed to turn off the IGBT as quickly as possible to minimize switching losses. This can be achieved by using a lower driver impedance and gate drive resistance. If the same gate turn-off rate is applied to overcurrent conditions, the collector-emitter di/dt will be much larger because the current change will be greater in a shorter time.

Therefore, to reduce di/dt and other potentially destructive overvoltage levels, it is important to provide a high impedance turn-off path when turning off the IGBT.

In addition to the above detection methods, it is also crucial to select the right IGBT. In most IGBT datasheets, the short-circuit current rating is generally specified, and there are several parameters to pay attention to:

VCC voltage, that is, the Vce voltage in the short-circuit test, or the bus capacitor voltage in the short-circuit test;

Vge voltage, that is, the driving voltage;

Rg driving resistance;

Test temperature, usually 25°C, but also 120°C or 150°C;

Some datasheets also specify the maximum number of repetitions for short-circuit tests.

VBsemi's IGBTs have the following advantages:

They have a higher voltage and current handling capacity.

They have a very high input impedance.

They can switch very high currents with very low voltage.

Voltage-controlled devices, i.e., they have no input current and low input losses.

The gate drive circuit is simple and inexpensive, reducing the requirements for gate drive.

They can be easily turned on by applying a positive voltage and turned off by applying zero voltage or a negative voltage.

They have low on-state resistance and high current density, allowing for smaller chip sizes.

They have a higher power gain and faster switching speed than BJT and MOSFET.

* 如果您需要申请我司样品,请填写表格提交,我们会24小时内回复您